Design is a creative process. Partnering with designers gives us the opportunity to support their creative vision. As a cut-and-sew clothing manufacturer, our focus is helping those designers bring their brands to market in an efficient, cost-effective way. To that end, our company guarantees that any garment we develop is production-friendly, key to the success of small batch manufacturing.

Why does production-friendliness matter? We'd like to highlight four key reasons why any new piece has to work from both a creative and a production standpoint for brands who seek product consistency and a substantial profit margin.

1. PATTERN AND PROTOTYPES NEED TO BE REPEATABLE

Some brands may tailor to a specific clientele who buy unique, one-of-a-kind items. Most designers are not in this select group, and want to do a production run of a specific garment. In the development stage, it is essential to determine whether we can make several of the same garment at a later point in time.

If a design is too complicated, it may be challenging to implement quality controls that ensure consistency of the later product. This may be the essential difference between coming to us to get a sample of your garment, compared to a tailor. While we are also dedicated to creating a beautiful piece, we have the additional insight to recommend how it might be modified to ensure your buyers know what to expect.

2. QUALITY CONTROL FOR A FULL RUN

Another factor is the ability to ensure quality control, not only on a sample garment, but on a later production run. We accomplish this in various ways, such as pattern making, universal markings, drill holes, and templates. These tools tell the sewers precisely where to place specific details.

If the pattern is not sufficiently repeatable, quality control is a substantial challenge. Every detail is important, from the placement of your brand label to the guage of the needle used to stitch the seams. When two items that are supposed to be identical go to market with obvious flaws, it reflects poorly on your brand -- something we want to prevent.

3. TRIMS THAT ARE FUNCTIONAL AND EASY TO SOURCE

Often, the trims in a garment reflect a designer's personal style. They are therefore not interchangeable with just any other element; they can compose an essential part of the piece. At the same time, they must stand up to use. You must be able to source them when time comes for a full production run.

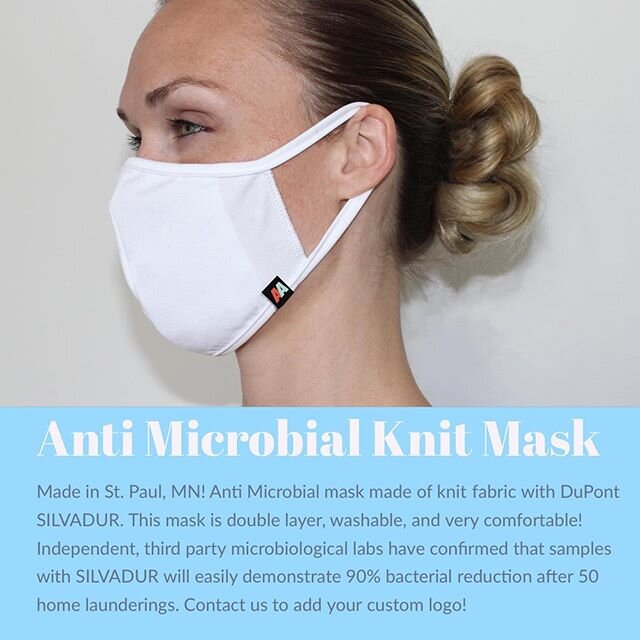

Part of our process is to closely analyze the trim, including snaps, zippers, buttons, and buckles, to confirm they are easy to order in bulk. The details that appear in the sample have to reflect what will go through the manufacturing process. They have to be durable, holding up to repeated washings and wearings by the final consumer.

4. DEVELOPING A COST-EFFECTIVE PRODUCT

In our work for brands, we are always thinking about the ultimate cost of production. This is front of mind as we analyze the trim and create the pattern. Often, we will work with the designer to break down the product if we sense it has become too complicated to be cost-effective.

Ultimately, we want our clients to have a product that's economically viable and consistent with their brand. To that end, we help them decide what's important in a design and what can be removed. The result is a strong partnership based on a shared vision of creating and selling a great textile product.

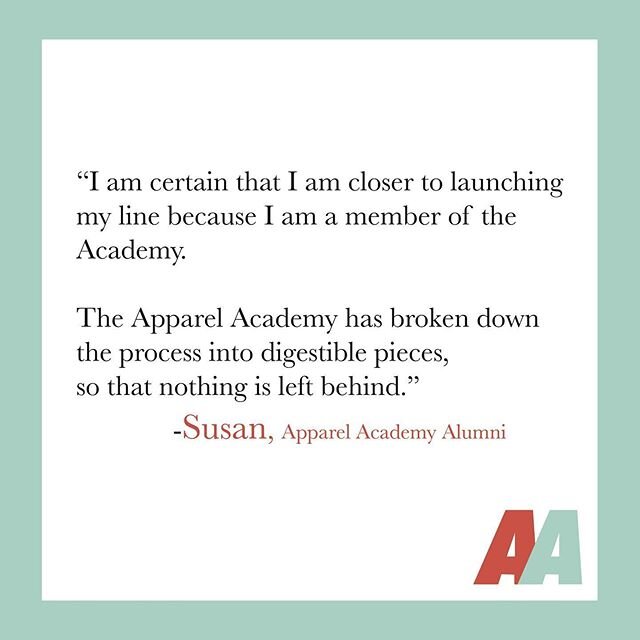

These are the kinds of perspectives we bring to our courses on apparel entrepreneurship, offered through The Apparel Academy.