Clothier Design Source became one of the first certified makers of the CCFC and is ready to help.

Back in June of 2020 the U.S. Army Combat Capabilities Development Command (DEVCOM) designed and developed Army face coverings based on the guidelines from the Center for Disease Control (CDC) and Department of Defense (DoD) and set out to find an industry partner to manufacture the face coverings. The cloth face coverings, known as the Combat Cloth Face Coverings (CCFC), are intended for Soldiers to wear when social distancing protocols cannot be met. Clothier Design Source, a cut and sew factory in Minnesota answered the call and began manufacturing and rapidly supplying the face coverings to the Army Air Force Exchange Service (AAFES). Since the recent resurgence of the coronavirus, Clothier Design Source is once again gearing up to supply Warfighters with the Combat Cloth Face Coverings.

Clothier Design Source is a Women Owned Business dedicated to making 100% Made in America soft goods. They have been around since 2006 and have a special focus on functional clothing and accessories. Since 2019, Clothier Design Source has dedicated most of its resources to provide the Army and Airforce with various products through awarded contracts or through AAFES.

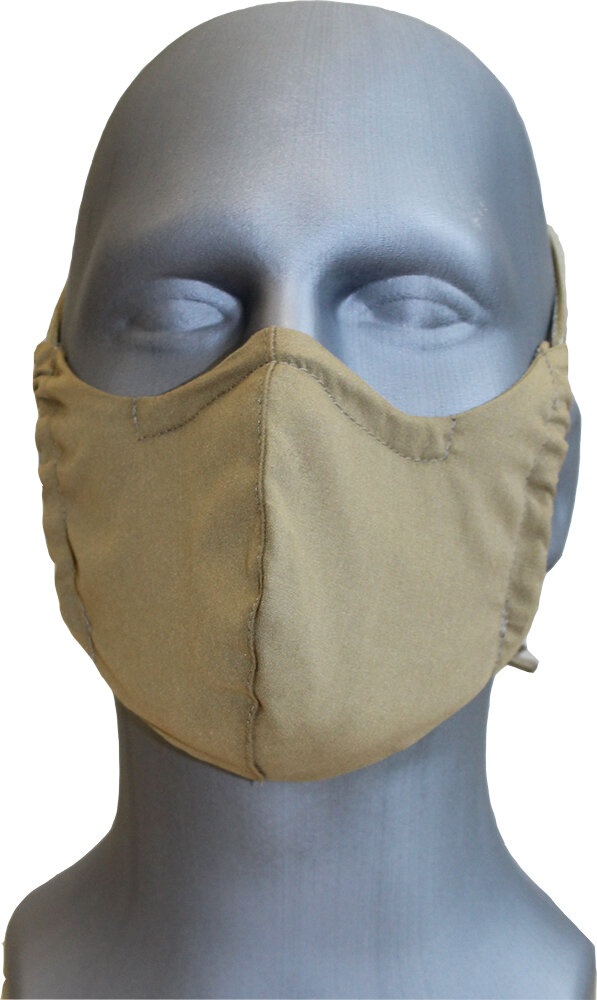

The CCFCs are face coverings that have been developed for uniform use and come in Black, Tan 499, Coyote 498 and Operational Camouflage Pattern (OCP). They are especially unique in their durability and designed adjustability. Clothier Design Source realizes there are not enough face coverings available to support the current demand and is currently in production to offer more.

The CCFCs were assigned a National Stock Numbers (NSN) following Clothier Design Source’s first substantial order in supplying AAFES with an initial order of 190,00 units. An NSN is a unique 13-digit numeric code assigned to products allowing any of the 29 NATO militaries to purchase the Combat Cloth Face Covering on a “military catalogue” basis, significantly simplifying the procurement process. The assignment of an NSN is also relevant to non-NATO customers in that it is considered to signify that the product has achieved a certain level of acceptance by the world's more discerning defense customers.

To learn more about all the features of the Combat Cloth Face Coverings, they can be found on ClothierDesignSource.com/combat-cloth-face-covering. The NSN numbers are as follows.

Class 4: Tan 499 Polyester/Cotton Plain Weave.

National Stock Number has not been assigned.Class 5: Black Polyester/ Cotton Plain Weave.

National Stock Number (NSN) 8415-01-692-4240Class 1: Tan 499 Nylon/ Cotton Ripstop.

National Stock Number has not been assigned.Class 2: Black Nylon/ Cotton Ripstop.

National Stock Number (NSN) 8415-01-687-8955Class 3: OCP Nylon/ Cotton Ripstop.

National Stock Number (NSN) 8415-01-690-6689Class 6: OCP Polyester/ Cotton Plain Weave.

National Stock Number (NSN) 8415-01-687-8956Class 8: Coyote 498 Nylon/ Cotton Ripstop.

National Stock Number (NSN) 8415-01-690-6692Class 9: Coyote 498 Polyester/ Cotton Plain Weave.

National Stock Number (NSN) 8415-01-690-5477